Quality Control CapabilityWe

have established ourselves as a reliable entity in the domain. We have

attained this position by paying attention to quality and delivering

dependable products. We deliver products to market after testing them on

several parameters. Our range is examined with the use of below modern

machines and equipment:

- Microscope Image system

- Micrometer Device

- Quadratic Element 2D Image Measurement

- Hardness meter

- Dynamic Balance Tester

- Quadratic Element Measurement

- High power Microscope Device

- Precision Height Detector

Our Modern Manufacturing EquipmentWe

are promptly meeting the global market demands for our products due to

our modern manufacturing facilities. We have made investment on

maintaining cutting-edge facilities that enhance our work speed and

provide precision. Following are the areas, where we have installed

latest machines and equipment:

- Grinding processing

- Precision Grinding Processing

- Large parts CNC Turning

- Wire cutting Processing

- Grinding Processing

- CNC Turning Machines

Customer SatisfactionIn

order to consistently increase our success rate, we pay high importance

to gaining customer satisfaction. We regularly conduct visit to

customers, establish close connections, and strive to become their loyal

partners.AchievementsWe

have already attained 14 patents of research and development

manufacturing products. In addition, we have already obtained tag of

being National High-Tech enterprise.Development History

In 2013, Deren Precision was officially established, and initially it mainly provided research and development of non-standard parts and non-standard tools for companies such as Foxconn Technology Group and Huawei.

As our customized processing services are recognized by customers, word of mouth spreads to various industries in the market, and cooperation has gradually entered large companies and multinational companies across the country, and at the same time exported to Thailand, Vietnam, the Philippines, Malaysia, South America, the Middle East and other countries and Taiwan.

The following is the growth process of our company:

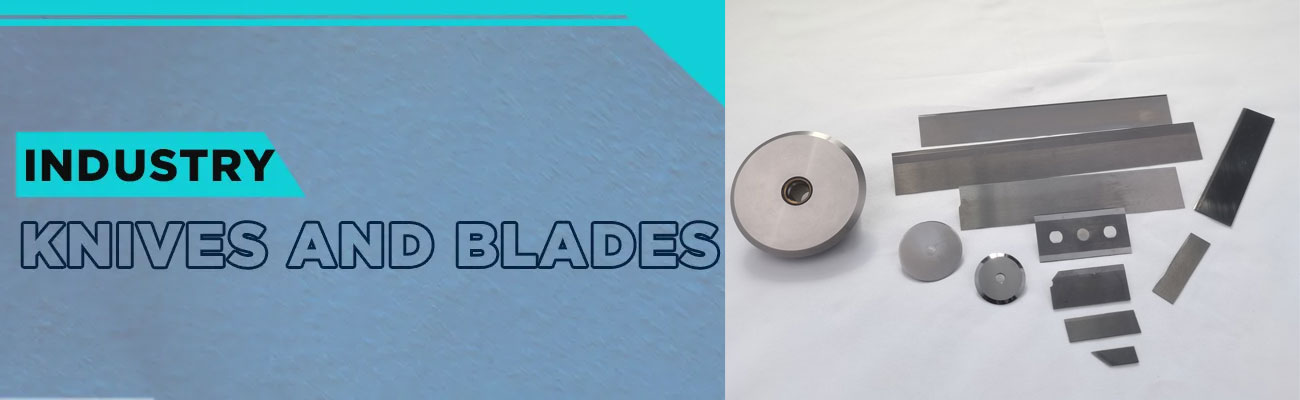

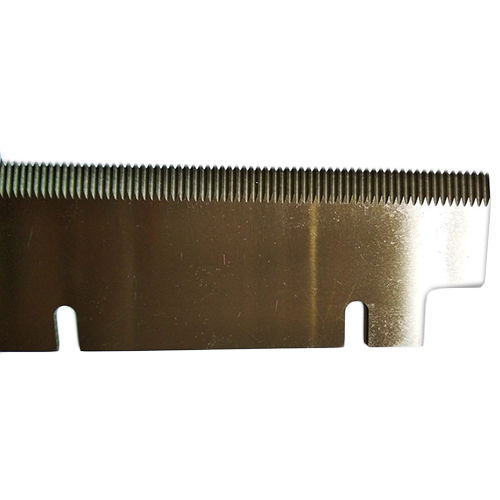

In 2013, we customized and developed long-life pelletizer core accessories for customers, and customized BKG pelletizer blades to replace German imports; in the same year, we customized FFC cutting knives and slitting knives to replace disposable blades imported from Japan, and the service life was increased by 15~20 times;

Customized high-temperature resistant ceramic tooling for university research laboratories, used for palladium material high-temperature electronic pulse experiments, protecting electrodes, and used in joint research and development with university laboratories; in the same year, developed a high-temperature resistant ceramic heat-embedded screw head fixture, which is specially used for the installation and protection of automobile lights, and its performance is better than similar fixtures imported from Japan; developed a dry cutting fixed knife, which is specially used for high glass fiber + ABS granulation, with a long life, high temperature resistance and corrosion resistance. For 5% to 30% fiber-containing materials, the load is about 3 tons per hour, and the average life is about 30 days, meeting customer quality and efficiency requirements. Manufactured a new type of structural alloy fixed knife and applied for a patent, and exported it to foreign markets at the same time;

In June 2013, we customized water filter strips for Taiwanese companies for use in BP-EP process dehydration machine extrusion, successfully replacing imports and mass production, providing customers with short cycle and cost-effective services;

In April 2014, we developed casting knives for the capacitor and resistor industries, which greatly increased their service life from 20 minutes to 5-8 hours.

In July 2014, we customized ceramic rings and ceramic guide rails for imported equipment for quartz wafer sorting and EFG testing, solving problems for customers and gaining recognition from customers;

In April 2015, we developed a German conical grinding cylinder for titanium dioxide grinding, which successfully replaced imports;

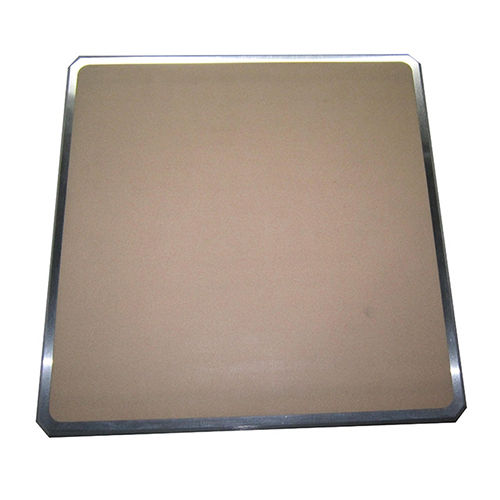

In August 2015, we customized 400x600mm large vacuum ceramic suction cup to solve the problem of large laser processing adsorption platform;

In May 2016, we customized a high-precision grinding roller for checkweighers and belt scales. It has high dynamic balance requirements, is quiet and wear-resistant, and has stable quality. After being equipped with sensors, it can compete with similar products imported from the United States.

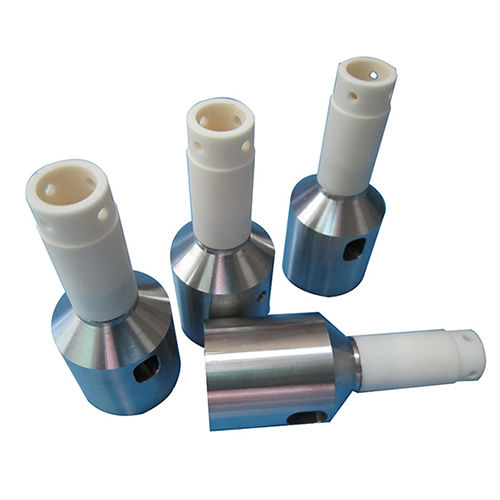

In September 2016, we developed high-pressure connectors for aircraft high-pressure gas transmission connections. They are precise and resistant to high pressure and are used for aviation equipment testing.

In 2017, we developed tungsten steel plates for curved glass forming molds, which are used for 3D curved glass forming and mobile phone glass panel hot bending equipment casting, with stable quality, small deformation and long service life;

In 2018, we customized and processed valve body tubes to provide precision flow valve body tubes for customers in the medical industry. They are used for fluid detection and testing. They are high-precision, corrosion-resistant, safe and stable!

In 2019, we developed high-hardness, wear-resistant screw-driving tools and sleeves, which were verified by the use in automobile assembly production lines and recognized by Japanese customers!

In 2020, we customized ceramic rollers for lithium battery coating machines and winding machines for the new energy industry. Insulation is required for the winding and slitting of cathode and anode materials to solve the problem of metal powder easily falling off and entering the materials during work. At the same time, we customized key accessories such as fixed winding needles, movable winding needles, isolation film cutters, tab cutters, and slitting spacers for customers.

In 2021, we customized dry film cutters, automotive film slitting knives, and 3M tape slitting knives for customers, with a lifespan 1.5 to 2 times that of similar products on the market.

In 2022, we will customize high-speed micro-hole nozzles for LED automation equipment, and customize ceramic nozzles and tungsten steel nozzles for the semiconductor industry, and obtain long-term cooperation qualifications.

Deren Precision keeps up with the forefront of the market, adopts new materials, new processes, cross-industry integration, multi-angle thinking, adheres to the concept of excellence and continuous improvement, and relies on our management and technical advantages. We have long-term cooperation with 50 large domestic enterprises, multinational companies, listed companies, university research institutes and scientific research institutions. We are always growing!

Looking forward to working with you to create value together!

Our Capabilities

In

order to promptly meet all the market demands for our product-line, we

have maintained modern facilities and dexterous team. We have

cutting-edge facilities for manufacturing, quality checking, and several

specific tasks. We are also powered by a strong manufacturing team,

which includes 10 craftsman who have over 20 years of precision

manufacturing experience. Due to our excellent resources, we are capable

of offering over 30000 custom parts and custom blades each month.